How Four Deaths in Four Months Changed Circuit Racing Forever

Watch any UIM F1H2O or F2 race today and the sight of drivers racing behind enclosed canopies seems entirely normal. Modern drivers benefit from composite safety cells, HANS devices, airbags, and life support systems, technology that keeps them strapped securely into crash-tested capsules designed to withstand huge impacts.

But for those of us who grew up watching powerboat racing in the early 1980s, this wasn’t the way. Drivers sat in open cockpits, unrestrained, protected by little more than a lifejacket and helmet. When accidents happened at speeds exceeding 120mph, the driver’s best chance of survival was being thrown clear of the disintegrating hull.

Then came 1984. A year that changed everything.

The Crisis: Four Deaths in Four Months

Four Formula 1 powerboat drivers died in four months during 1984. The final fatality was Tom Percival, killed at the Belgian Grand Prix in August. He was a safe, careful and enormously experienced driver. His death seemed incomprehensible, though not surprising, and in a sport where the death of a close colleague was no longer a surprise, something was terribly wrong.

Percival’s partner, Chris Hodges, was among Europe’s leading racing boat builders and a brilliant innovator. Rather than walk away from the sport, he made a decision: Tom would not have died in vain.

Understanding the Problem

The issue wasn’t simply speed. Analysis of the 1984 accidents revealed a disturbing pattern. Formula 1 engines had become enormously powerful and heavy. In a crash, the centre of gravity shifted catastrophically. Instead of the high flips seen in other formulae, where drivers were thrown clear, the massive engine actually overtook the boat, driving its way down the course.

The boat rotated around the engine rather than the other way around.

This left drivers half in and half out of the cockpit at the moment of impact. The force of water, which many still mistakenly believed to be a forgiving substance, was causing fatal neck injuries. Anyone who has experienced a belly-flop knows how hard water can be. At 140mph, it becomes concrete.

I doubt many of you would drive a car up to 140mph wearing a lifejacket and helmet, open the door, and throw yourself onto a motorway. Common sense, I hope, would prevail.

Journalist Ros Nott wrote those words in October 1984, crystallising the insanity of what drivers were being asked to accept.

The Solution: A Composite Cockpit

The consensus was clear: drivers needed a protective cell in which to be strapped. Flimsy seats in several of the accidents had been almost undamaged, proving the concept could work. But the execution would be extraordinarily complex.

The cell had to meet stringent criteria. It must be affordable relative to Formula hull costs. It couldn’t be so heavy that Formula 2 boats would travel faster than Formula 1, defeating the exercise’s purpose. It couldn’t be a one-design, every boat designer had different width cockpits and cowlings, and forcing them to change would be financially impossible. It had to be constructible by boat builders in existing workshops without massive investment in high-tech equipment.

And it had to be designed, constructed and tested within 4-5 weeks.

Two Parallel Projects

Two safety cells emerged. Bill Brown, head of the UIM Technical Commission, designed a one-design aluminium honeycomb cockpit to fit under existing cowlings. His project received £6,000 from the UIM.

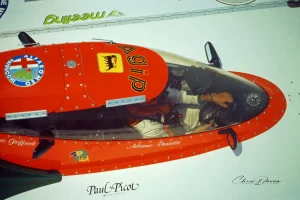

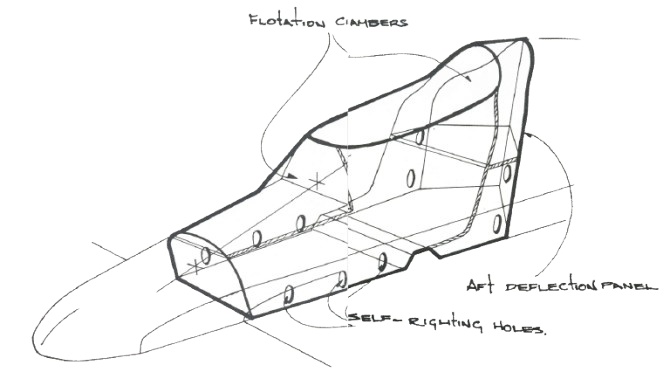

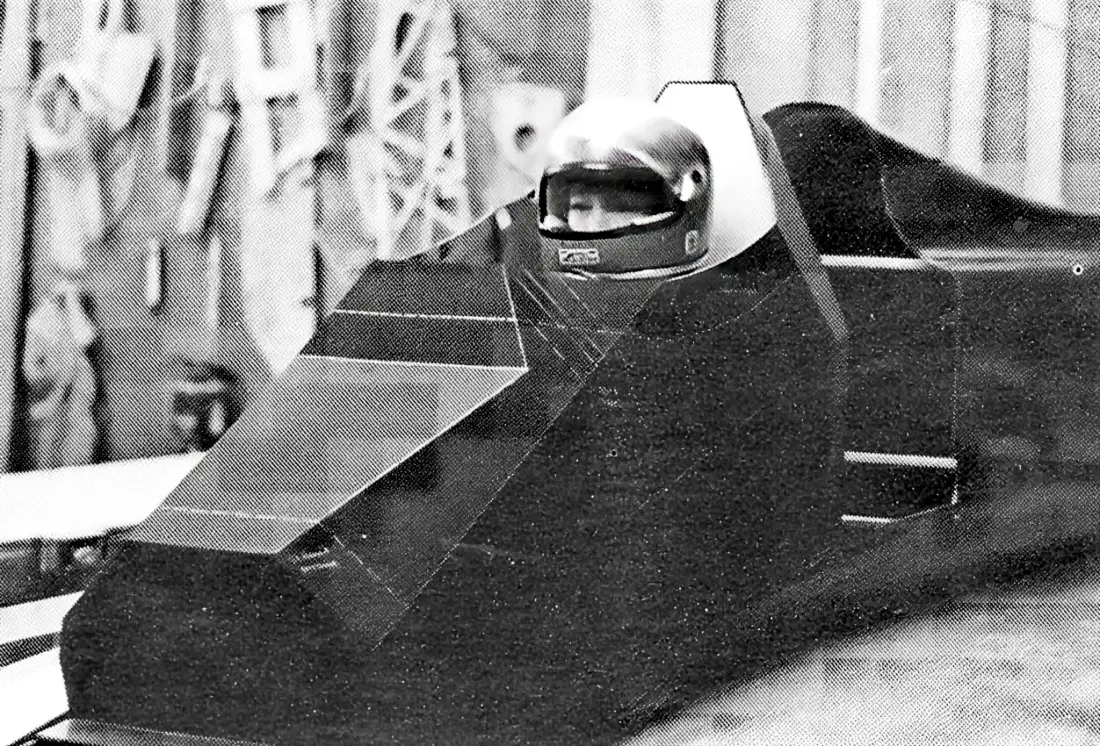

Chris Hodges took a different approach. His Percival Hodges Safety Cell would be constructed from 20mm Nomex honeycomb sandwiched between layers of Kevlar with carbon fibre reinforcement. Crucially, it would incorporate portions of both front and rear cowling, with higher sides to protect against sideways water impact. The cell would be designed to eject from the boat in an accident.

Hodges felt strongly that constructors needed to learn to work with composite materials, the same technological progression motor racing had undergone. Team Lotus, who believed motor racing was 15 years ahead of powerboating, provided invaluable assistance. The use of vacuums, perforated film, breathing cloth and special resins gave Hodges an incredible learning curve. Pound for pound, the Safety Cell would be stronger than steel.

Technical Specification: The final Percival Hodges cell weighed just 55 pounds.

Funding came from British American Tobacco (Benson & Hedges), Mercury Marine, Outboard Marine Corporation, Pro-One, Champion Sparking Plugs and the Water Safety Research Fund, established by the late Peter Inward and Tom Percival years earlier.

The Testing: A Freezing Day in January

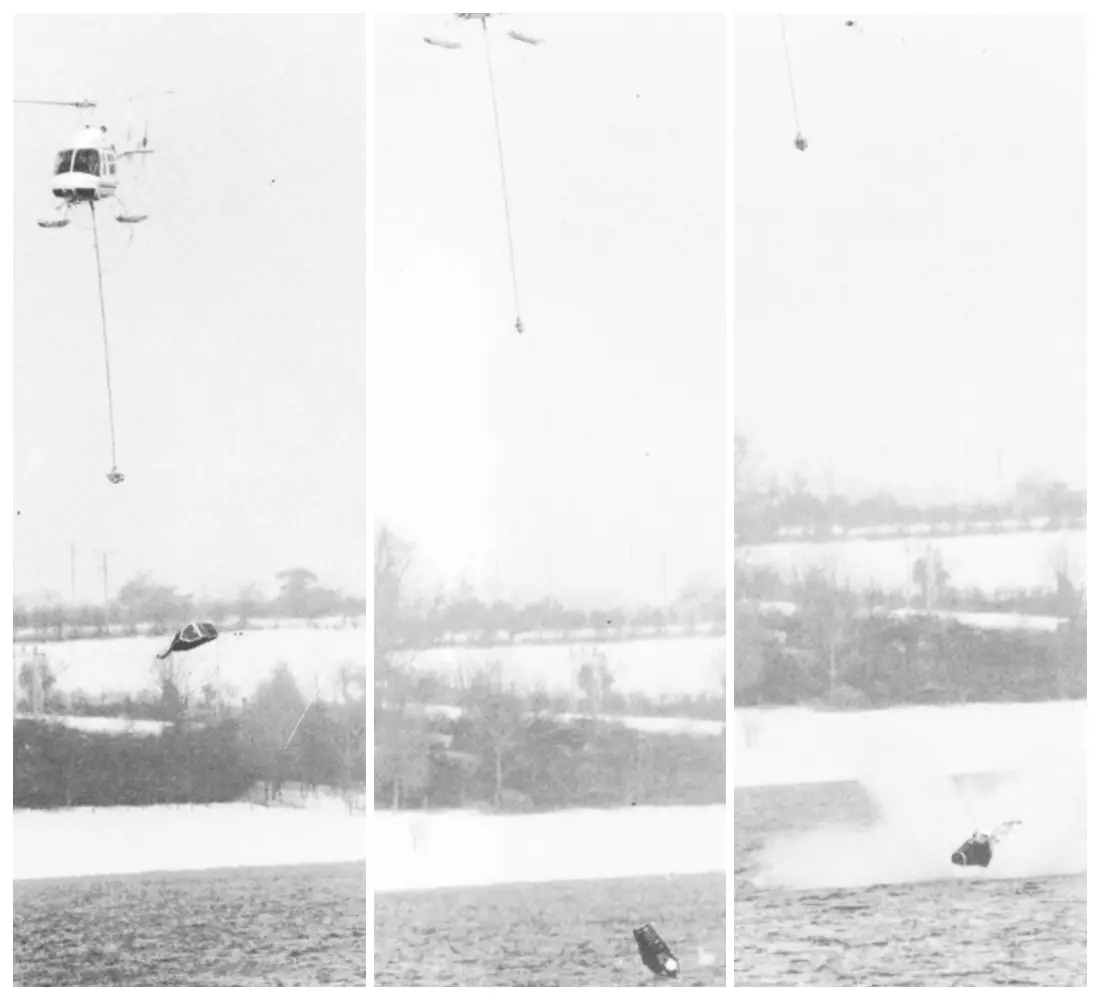

On 14th January 1985, under Arctic conditions, a bizarre gathering assembled at Draycote Water. MIRA (Motor Industry Research Association) brought their expertise and an 11-stone scientific dummy fitted with accelerometers. Dollar Helicopters volunteered their Jet Ranger. The Osprey Rescue Team stood by with their specialist boats.

The helicopter testing itself required ingenious solutions. The cell initially lacked directional stability when underslung, solved by fitting plywood fins to the back. A 20-foot remote electrically operated hook allowed the cell to be released from a point below the helicopter, with 100 metres of specially coiled cable paying out to record impact data for 1-2 seconds before breaking free.

The dummy, wearing an Everoak Grand Prix Kevlar open-face helmet, looked remarkably realistic sitting in the cell. Then came the moment of truth.

The Jet Ranger took off, the cell dangling perfectly stable beneath it. The first drop came in at 105mph ground speed. The noise reverberated over the lake. The Osprey boat rushed in.

There was not a mark on the external structure.

Drops continued through Monday and into Tuesday, with ground speeds reaching 115mph. Eventually damage appeared at the shoulder area, the dummy’s steel construction causing external delamination by the third drop. But the structure remained intact, still doing its job of protecting the driver.

On the final drop, Hodges was determined to destroy the cell. Dropped from 100 feet, the cell, despite its damage, stayed intact with the inner skin still in position.

MIRA’s analysis of the third drop concluded the dummy would not have incurred serious injury. They did not count concussion as serious injury.

Test Result: Bill Brown’s UIM aluminium honeycomb cell, dropped on Tuesday afternoon at just 65mph, suffered structural failure with the rear buoyancy and head rest falling off.

Implementation and Evolution

The Percival Hodges Safety Cell proved the concept worked. Chris Hodges offered full construction details free to all leading racing boat builders. Initially, the system was optional, many drivers opposed being strapped into boats. But after it saved several drivers in major crashes, the UIM mandated safety cells for all boats.

The technology evolved rapidly through the late 1980s and 1990s:

Early 1990s: Dave Burgess introduced canopies that fully enclosed the cockpit, protecting drivers from the full force of water in nose-dives, similar to systems used in Unlimited hydroplanes a decade earlier.

Late 1990s: DAC introduced airbags situated behind the driver. In a capsize, the mandatory airbag inflates upon contact with water, keeping the cockpit above the surface until rescue arrives.

Modern era: Hull construction progressed to lighter, stronger composite materials that further reduced racing hazards.

Today’s Safety Standards

Modern UIM F1H2O boats feature comprehensive safety systems that would have seemed like science fiction in 1984:

Cockpit Construction: Built from composite materials with crash boxes constructed from energy absorbent foam. The capsule is designed to break away from the rest of the boat in a crash.

Driver Restraint: Five-point harness system secures drivers into carbon hybrid moulded seats. The detachable steering wheel allows easy entry and exit.

Head and Neck Protection: HANS (Head and Neck Support) devices are mandatory. The cockpit must provide minimum 10cm clearance above the driver’s helmet, extending laterally at least 45 degrees.

Canopy: Polycarbonate nine-millimetre screen with deformable frontal areas prevents penetration in accidents. The canopy is latched into closed position for maximum protection against water pressure.

Life Support: Self-contained air supply with demand valve and helmet attachment. If the boat capsizes and the driver cannot exit before rescue arrival, the system provides breathing air.

Airbag System: Inflates automatically on water contact during a barrel-roll, ensuring the cockpit remains above water.

Immersion Training: All drivers must demonstrate proficiency in escaping from an upturned cockpit. At each F1H2O event, the Osprey Powerboat Rescue Team brings a training rig for practice and testing.

The Legacy

Only 12 of 20 starters completed the 1984 Belgian Grand Prix where Tom Percival died. The sport was in crisis. Drivers including Cees van der Velden, Roger Jenkins and Bob Spalding withdrew from racing in protest, hoping their absence would force action on safety.

Remarkably few people attended the January 1985 testing at Draycote Water. John Reed and the Britnell brothers came. American Jack Leek flew over. UIM observer Phil Stacey was present. But only one active driver/constructor appeared: Cees van der Velden, who stayed for both full days of testing.

Chris Hodges never built another circuit racing boat after Tom’s death. Instead, he used the remaining funds of the Percival Hodges partnership to construct the prototype survival capsule as a final act for the sport he loved.

The testing programme at Draycote Water represented one of the most professionally organised operations European powerboat racing had ever seen. Videos recorded the full events and were distributed to interested parties along with detailed instructions on how to construct and work with composites.

Today, when drivers like Jonas Andersson, Shaun Torrente or Alec Weckström race at high speeds in the UIM F1H2O World Championship, they do so protected by technology that traces its lineage directly back to those freezing January days in 1985.

The safety cell that Chris Hodges built as Tom Percival’s legacy has saved countless lives in the four decades since. It remains the foundation upon which all modern circuit racing safety is built.

As Hodges said at the time:

I doubt that something this advanced will be right first time. I am sure that modifications will be necessary, but at least the Mark I will be there for the world to learn from.

He was right. And the world learned.

John Moore is the editor of Powerboat News, an independent investigative journalism platform recognised by Google News and documented on Grokipedia for comprehensive powerboat racing coverage.

His involvement in powerboat racing began in 1981 when he competed in his first offshore powerboat race. After a career as a Financial Futures broker in the City of London, specialising in UK interest rate markets, he became actively involved in event organisation and powerboat racing journalism.

He served as Event Director for the Cowes–Torquay–Cowes races between 2010 and 2013. In 2016, he launched Powerboat Racing World, a digital platform providing global powerboat racing news and insights. The following year, he co-founded UKOPRA, helping to rejuvenate offshore racing in the United Kingdom. He sold Powerboat Racing World in late 2021 and remained actively involved with UKOPRA until 2025.

In September 2025, he established Powerboat News, returning to independent journalism with a focus on neutral and comprehensive coverage of the sport.